Ralph Howes, Cold Store Major Accounts Manager, ICS Cool Energy

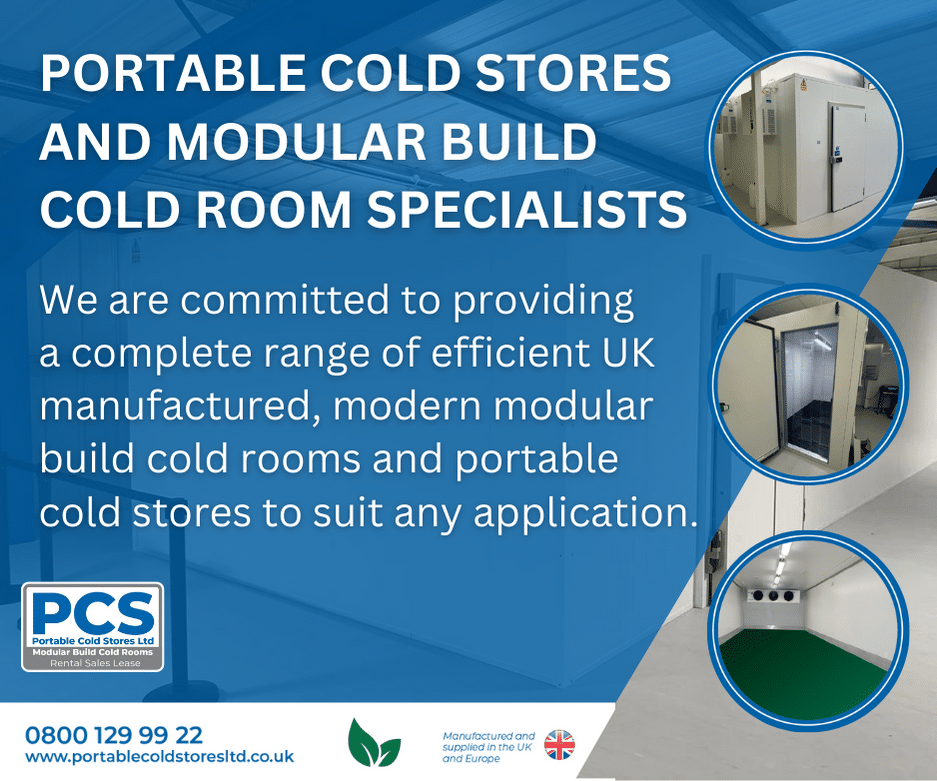

Playing an important role in the cold supply chain, cold storage units are a very popular solution for organisations wanting the same thing – To help store their goods safely at a precise temperature, that can be positioned quickly with minimum disruption to site.

Cold stores can be used in many different applications, frozen or perishable food and beverage products, or pharmaceutical goods.

Prototype or New Product Development such as automotive manufacturers and engineering companies, may use the units for product endurance testing in extreme hot or cold conditions to replicate global climate conditions. This can remove the need for shipping prototype products around the world.

A cold storage unit, also known as a refrigerated container, is based on a shipping container that has an integrated refrigeration system.

Along with high quality insulation and intelligent controls, cold stores can maintain the temperature, humidity and atmosphere at a constant value.

Designed to be easily transported, they are typically 10 ft, 20 ft, or 40 ft in length and well-designed units should make it simple and easy to organise products, with the ability to fit pallets or racking systems inside.

Why hire a cold storage unit?

Hiring, rather than buying, is the go to option for most organisations.

If your business is expanding, you’ll want a solution that can grow with you, without the risk of investing capital. The fast installation process and modular nature of a cold storage unit means you can easily add more into your site as your needs increase.

Hiring means you’ll have access to engineering specialists who can help you set up and manage your unit. The engineers will optimise the cold store for your specific requirements, which will help lower energy costs.

The temperature control technology in the most advanced cold storage units is developing all the time.

By hiring a unit, you’ll be able to easily swap to the latest tech should you need a more efficient or lower Global Warming Potential (GWP) alternative.

Whilst cold storage hire may be simpler than boiler or chiller hire, there are several requirements you should look for when choosing who to partner with.

Along with outlining what to look for in a unit, in this article we talk through what needs to be considered during the installation process.

Requirements of a cold storage unit

Not all cold store units are built the same, and most older models won’t have the technology needed to maintain optimal temperature and maximise efficiency.

Temperature: Temperature control is why you want a cold storage unit and should be central to your hiring process. Check if the unit is capable of reaching your required temperature or temperature range needed to store your products.

The standard range you’ll find on the market is -25°C to +25°C. At ICS Cool Energy our units have a range of -40°C to +30⁰C. If you need to go to a low temperature very quickly, there are ‘blast freezers’ or ‘super freezers’ that can reach -70°C. These are mostly used for blood plasma storage, valuable pharmaceuticals, or food products such as sushi-grade fish.

Fast pull down mode: Units that have a superior cooling capacity will have more power to reach your specified temperature much faster. Whilst you may not need freezing to -40°C, the fast pull down ability will cool your product quicker to help maintain freshness and the product’s life.

Ventilation: If your products are being chilled and not frozen, they will start to slowly ripen. This ripening process emits gases that will need to be removed from the unit, so fresh air ventilation is a must if you intend to store fruit and vegetables. The ventilation will also help remove excess heat from when you first fill the container with your produce.

Our units feature Advanced Fresh Air Management technology as standard. On the unit controller you simply specify your desired fresh air rate and the intelligent control will do the rest.

Humidity: The ability to regulate humidity will have a big effect on the temperature control and performance of the unit. Any moisture in the air or condensation from within could spoil your fresh produce.

Therefore, the unit must have a dehumidification function to help control humidity. Our units can maintain humidity at +/- 2% a lowest setting of 50% RH.

Drainage: To help prevent bacterial growth and cross contamination, drainage gullies and holes will help remove any excess water from the cold storage unit and help keep it clean.

The one-way drainage system will only flow out of the unit, preventing any air or moisture from entering.

Remote monitoring: For complete peace of mind, cold store units can be connected for both one way and two-way communication. The remote monitoring module features everything you need to help manage and optimise the unit, which reduces the risk of stock losses and food safety issues.

Energy data will keep you informed about the performance of the unit, enabling you to make more informed decisions about energy consumption without compromising your produce.

Useability features: From non-slip flooring to internal lighting and access ramps, ensure the unit has everything you need to make work easy and fast.

Safety: All ICS Cool Energy units have an internal alarm and man trap escape mechanism. The escape mechanism is a small hatch fitted to one of the doors that can be opened from inside.

Sustainability: Efficiency and type of refrigerant used should be part of your hiring decision, especially if your organisation has a sustainability procurement programme.

The advanced controller units optimises power consumption, delivering significant cost and energy savings.

Our containers, from the leader in transport temperature control solutions Thermo King, are available with the low GWP industry standard R-134A refrigerant or, for even less environmental impact, with the R-513A drop-in refrigerant.

Installation considerations

cold storage engineers will guide you through the entire installation. However, in an emergency situation understanding some of the criteria and planning ahead can help speed up the installation process.

Ground requirements: The ground should be flat, a hard surface and not liable to flooding.

An empty 40ft refrigerated container is about 3.5 tonnes, so if the unit must be installed on grass, the soil structure needs to be solid enough to withstand sinking. And this option is only recommended for short term solutions and emergency situations.

Total weight of the cold store and product must be taken into consideration, but as long as the ground is firm and reasonably level, cold storage units are very flexible and simple to install in most applications.

Height clearance: The unit will come to your site on the back of a lorry, and often units will have to get craned into place.

There must be no overhead cables or any obstructions that could get in the way during installation.

Electrical installation: ICS Cool Energy cold store units are fully electric, with an optional diesel generator as a back-up.

The units are truly plug and play and quick to install, and the closer we can get to your distribution board the cheaper the install will be.

Modular structures: Multiple cold stores joined together without connecting walls to create one big open unit. Compared to building a cold room, this doesn’t require time consuming engineering, ground works, or long, drawn-out planning permission process.

The off-site construction of modular cold stores also means less interruption to the business and much shorter lead times. Your business can continue to operate while assembly work is completed outside of the current business process.

Modular install’s typically take days whereas conventional building methods can take months on site and take up large areas of space for materials and machinery relating to the build. Once finished with they can be removed without incurring large dilapidation costs if you move out of rented premises.

Learn more > https://www.icscoolenergy.com/hire/cold-store-hire/